Why you should recycle

Recyclers like us purchase end-of-life scrap vehicles and ensure that all vehicles are recycled in an environmentally sound manner. No other product on earth is recycled to a greater degree than the automobiles. Used, not road worthy vehicles can offer very good source of reusable parts for recycling. Auto recyclers spend significant resources to build and maintain facilities specially designed to recycle parts, to capture and store harmful materials like lid from car batteries, gasoline, motor oil, transmission oil, antifreeze fluids, AC gas and keep them from contaminating soil, groundwater and air.

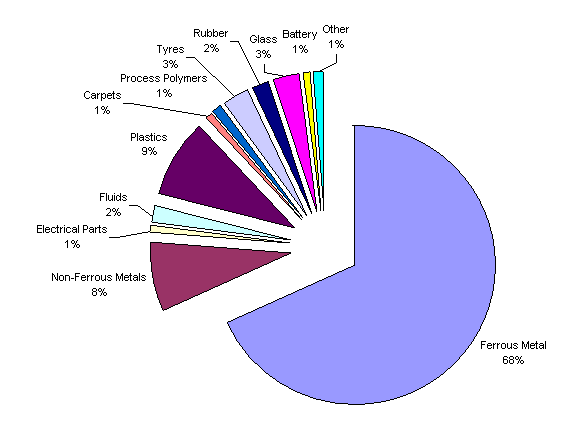

The composition of a typical car has changed substantially in recent years. For example, ferrous metal content has decreased significantly as lighter, more fuel-efficient materials such as plastics are incorporated into vehicle design. An analysis of vehicle manufacturer data for around seventy popular car models shows the following breakdown of materials (by weight)

The world’s automotive industry made over 66 million cars, vans, trucks and buses in 2005. Newer vehicles are better for the environment cause they are CO2-efficient, because they use less fuel. Billions of Dollars are invested annually throughout the world by different car companies in refining and improving conventional petroleum-burning engines, making them more efficient by managing the process of combustion through improvements like electronic control of fuel injection, air flow and valve timing.

Vehicle energy consumption is being cut using a wide variety of improvements from lightweight and low friction materials, through optimised manual and automatic transmissions, stop-start control and regenerative braking to electric power-steering and low-energy lighting. Increasing the share of clean diesel cars can further improve the fleet’s fuel efficiency. Today, in the European Union alone, more than a million vehicles emitting less than 120 grammes of CO2 per kilometre (the European Union’s very ambitious target for the fleet average) are sold every year and the endeavour continues to drive down CO2 even further.

The average 14 year old vehicle produces 19 times more smog-forming emissions than a new vehicle. Cars are the number one most recycled product on the planet. 75% of an average car’s content by weight can be recycled. No other complex mass-produced article has so far achieved such a high rate of recycling.

What happens after your vehicle get Picked-Up?

Once your vehicle has been picked up or received by one of our location, it will be recycled at the facility in an environmentally responsible way. This recycling process happens in three stages:

1. Pre-treatment: drainage of operating fluids

2. Parts Re-use: dismantling of parts and components

3. Recycling of Materials

Stage One – Pre-Treatment

Preparation of a vehicle for dismantling is vital to proper recycling. This includes the drainage of operating fluids such as oil, coolants, refrigerants and fuel, and the removal of the gas tank, battery and tires. It is critical that the draining and proper collection of fluids is performed to prevent any groundwater contamination. The average volume of operating fluids in a car is approximately 20 litres: For example

Engine Oil =2.8 Litres Transmission Oil =1.6 Litres

Final Drive Oil =1.2 Litres Coolant Fluids =3.00 Litres

Steering Gear Oil = .08 Litre and Fuel = 11.30

Once the fluids and other materials have been removed, they are used, re-used or responsibly disposed of. For example;

Oils and Greases:

Re-used by the auto recycler or removed to a licensed recycling facility.

Coolant, Fuel, Windshield Fluid:

Re-used by the auto recycler or sold to their customers.

Refrigerants (CFCs, HCFCs):

All air-conditioning systems are evacuated by a trained technician. The used refrigerant is sold to a licensed buyer for re-use.

Gas Tanks:

Punctured, drained and recycled for the metals.

Battery:

This component is either re-sold or removed by a licensed recycling facility.

Mercury switches:

Removed and collected and sent to Summerhill Impact’s Switch Out Program www.switchout.ca for mercury recovery and storage.

Tires:

In the absence of a recycling program to deal with rubber from used tires, good quality tires are sold domestically or exported. The remaining tires are exported as a fuel source, used for noise and energy absorbing components, or stockpiled by tire recyclers.

Stage Two – Parts Re-use

Older parts are recycled for scrap metal only. Newer parts & components depending on their condition and sales potential are dismantled, reconditioned and sold to customers. This minimizes the need for manufacturing new parts.

Stage Three – Recycling of Materials

Once all the fluids have been drained and the re-usable parts have been removed, the automotives then are sent to an automobile crusher to flatten the vehicle hulk. These flattened hulks are shipped to shredders which pulverize the car into fist-sized pieces in minutes. The valuable ferrous and non-ferrous metals are removed magnetically, and with complex floatation systems. The non-metallic components, known as Auto Shredder Residue (ASR) or fluff, are landfilled. ASR is composed of rubber, plastics, fabric, dirt, foam, glass and metal particles. That is why it is critical to ensure that the hazardous components are recovered before the car is crushed and shredded. Research continues to determine ways to reduce the amount of ASR diverted to landfills, both at the manufacturing and recycling stages in the life of a vehicle.